The expertise in rotating machinery condition monitoring, combined with world class

laboratory facilities, enable us to develop advanced signal processing techniques

capable of online condition monitoring under constant and fluctuating operating conditions.

Expertise

Online condition monitoring under fluctuating operational conditions:

- Gearboxes.

- Generator end windings.

- Haul roads.

- Turbomachinery blades.

Online turbomachinery blade vibration measurements:

- Blade tip time of arrival.

- Photogrammetry.

- Laser vibrometry.

Torsional vibration measurements:

- Shaft encoders.

- Zebra strip encoders.

Equipment and Software

Activities are supported by the following infrastructure:

Bently Nevada rotor dynamic kit.

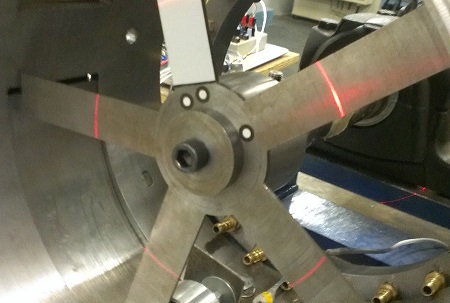

Turbomachinery blade vibration test bench.

Wind turbine experimental structure:

- Realistic blade loads.

- Variable speeds and loads.

- Gearbox testing.

Gear fatigue test bench:

- Variable speeds and loads.

Current focus research areas include blade tip timing, rotor dynamics and condition monitoring of machines under fluctuating operational conditions. Typical clients include power utilities and power plant engineering companies, research councils and innovation agencies.

Clients and Typical Projects

Online turbomachinery blade vibration measurements.

- Eulerian measurements with continuous microwave sensors on an axial-flow induced draught fans.

- Blade tip time of arrival measurements on a 20 MW compressor.

Online condition monitoring of machines under fluctuating operational conditions:

- Air cooled condenser fan gearboxes.

- Large horisontal mill gearboxes.

Online condition monitoring of large generator end windings.